The primary reason for using industrial compactors is to reduce waste management costs by compacting non-recyclable materials for disposal. Compactors are able to reduce the volume of waste materials by up to 75% which not only reduces transportation and storage costs, but also saves space in landfills. Read More…

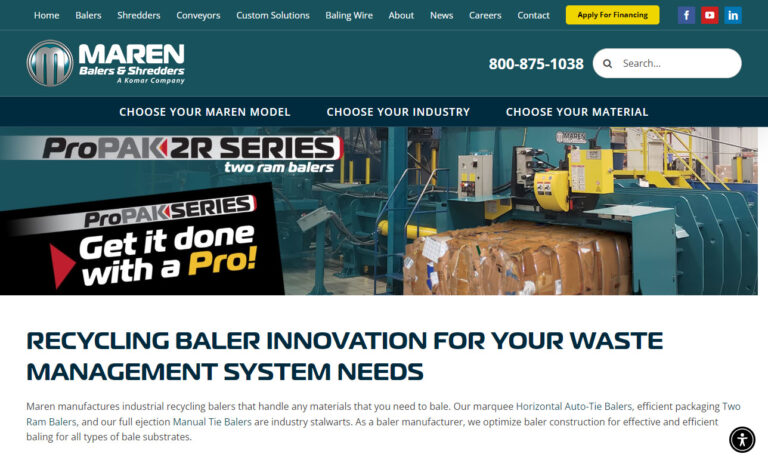

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

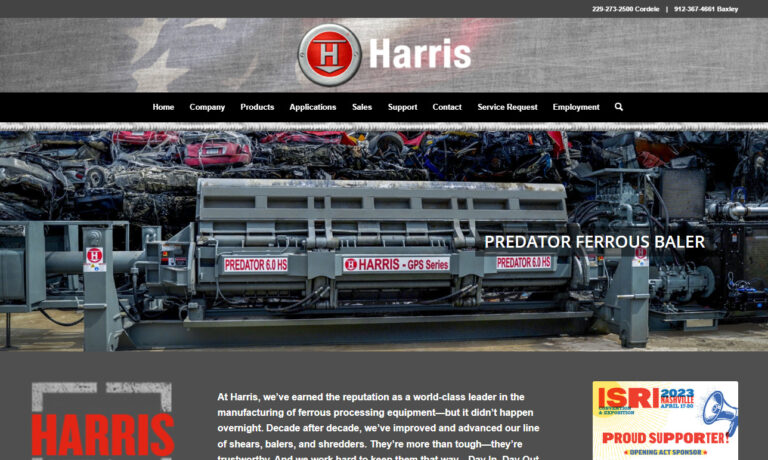

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

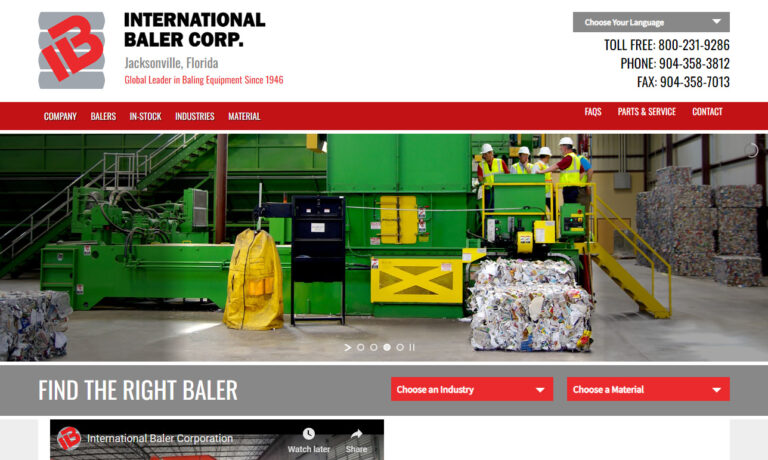

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Industrial Compactor Manufacturers

The use of industrial compactors reduces the bulk volume of waste materials, reduces the money and effort required to dispose of them and leads to savings over time. Compactors tend to be smaller units than industrial balers and form more compact bundles of waste material. Industrial compactors are used by marine, food waste processing, aerospace, medical and industrial manufacturing.

Materials that can be processed by industrial compactors include: textiles, food products, drums, rubber waste, metal scraps, plastic and fibrous metals and almost any type of waste. However, aerosol cans, batteries, flammable or explosive materials and poisonous materials should be disposed of in approved ways. Compactors can be fitted with extraction capabilities which are able to remove any liquids or moisture residue in the waste material.

Styles of compactors include: stationary, self-contained, vertical or horizontal, as well as designs for material-specific or industry-specific applications. Industrial compactors are composed of three main components: a large metal chamber, an electric motor and a hydraulically or pneumatically powered press. The compactor is loaded manually or automatically through an input area and the waste material is fed into a chamber where it is pounded, smashed and flattened unto a compact size.

The electric motor powers the press which is required to exert a great amount of force upon the waste materials. Using a hydraulic system helps to reduce the amount of heat produced by the process, and to minimize energy loss. When the press reaches a set pressure point and the waste material can be no further compressed, the machine reverts to its original position and the compressed waste can be removed. Commercial compactors, such as trash compactors, usually use bins or bags to store the freshly compressed materials, but industrial compactors typically produce bales of waste material.

Compactors play an important role in helping manufacturers to be environmentally responsible in terms of waste management and disposal and in reducing the carbon footprint of industrial activity. They reduce the frequency of waste removal, minimize the potential for overflowing waste and contaminants, provide more hygienic environments and improve facility maintenance.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services