The trash compactor is a device that reduces and compresses various materials using hydraulic, mechanical, or pneumatic power. Most businesses that produce trash also employ compactors. This device compresses waste before putting it in a container. When the container is full, it is replaced with a fresh one and then sent to a landfill or processing facility. Trash compactors come in different sizes and can be customized to a business’s needs. For example, a compactor can reduce the amount of bulky waste before it is picked up by a hauler, free up space on a property, make staff waste collection easier, and lower transportation, collection, and disposal expenses. Read More…

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Trash Compactor Manufacturers

Types of Trash Compactors

Vertical Compactors

Vertical compactors are front-load compactors. They are perfect for usage in cramped, compact locations because of their modest footprint. Self-contained and vertical compactors are similar, except that the vertical compactor uses a press to compact trash. One can place plastic, cardboard, paper, and moist garbage into a vertical compactor through the front entrance.

A switch activates a vertical compactor's ram when the chamber its full, causing the ram to descend and compress the garbage. The main advantage of a vertical compactor solution is that it will take up less room than a standalone compactor. In addition, a block or bale made using a vertical compactor can be recycled. Finally, one can set up a vertical compactor for front or back load pickup.

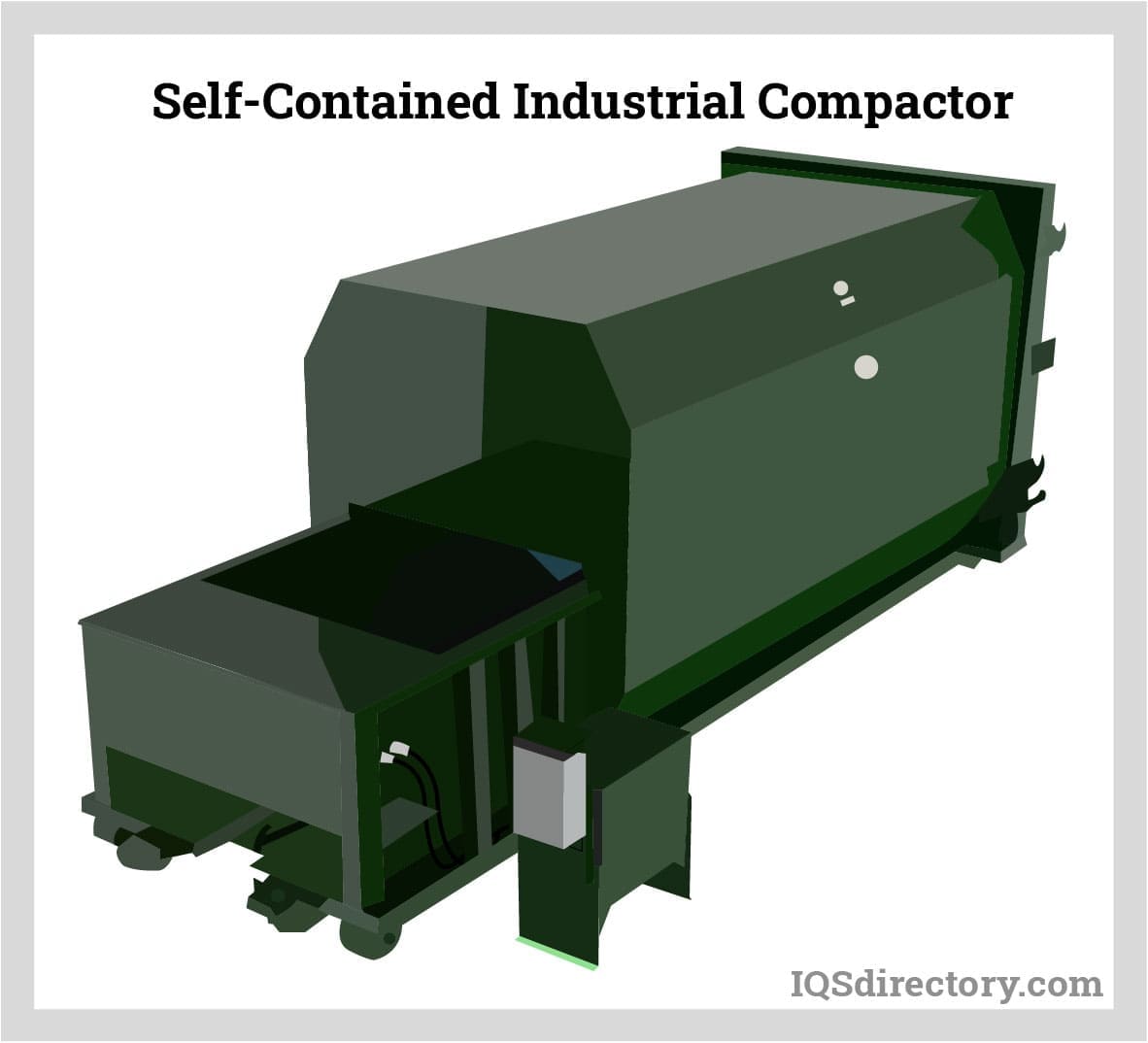

Self-Contained Compactors

Self-contained compactors are perfect for use in food processing facilities because they are made with the capacity to store and crush wet waste as their primary function. Typically, a self-contained compactor is fastened to a structure with an entrance that enables loading from inside the structure. Typically, one can find these models outside, behind a store.

Wet waste is placed inside a self-contained compactor, where the ram crushes it to reduce its volume by 75%. Self-contained compactors are an excellent option for restaurants and other establishments that produce liquid and food waste. Odors are contained within a self-contained compactor, They are also sealed to prevent liquids from spilling and falling to the ground.

Stationary Compactors

Stationary compactors are made for high-output activities that generate tons of dry, brittle garbage. A stationary compactor can load rubbish from the ground and compact it into an additional attached waste container. These compactors work effectively for grocery stores, hospitals, industrial facilities, and retail establishments that produce much waste. Stationary compactors then allow one to fill a trash container by using their hands or through a conveyor system.

The stationary compactor can crush dry garbage. Since this compactor is not self-contained, one should not use it for wet garbage. Moreover, users can deposit waste from a high-rise structure by attaching a chute to the top of a stationary compactor. Their design is suitable for business buildings, lodging, and medical facilities with a limited garbage compactor area. A stationary compactor may compact cardboard, mixed paper, plastic, and textiles, among other materials.

Indoor Trash Compactors

A trash compactor for indoor use is made to fit within an establishment. An indoor trash compactor is used to compress rubbish into "cubes" that can be conveniently moved to a dumpster using a lift cart that typically comes with these compactors. Fast food joints, schools, hotels, full-service restaurants, small retail businesses, cruise ships, and casinos are all ideal locations for this garbage compactor solution.

Applications of Trash Compactors

- Hospitals utilize trash compactors because they are ideal for disposing gloves, hospital waste, gowns, personal protective equipment (PPE), and more, including laboratory waste, shoe covers, and exam table paper.

- Trash compactors are used in houses and apartments to increase hygiene and eliminate garbage. They are superior to trash bins because they take up less room and are made of materials that won't leak.

- Trash compactors are used in grocery stores to attract customers by removing spoiled goods and eliminating the odors associated with these unwanted items.

- Trash compactors can be used in steel and hardware businesses to enhance safety and cleanliness around the workplace.

Benefits of Trash Compactors

Recognizing the Advantages and Costs

The price goes up if a business needs more trash pickups. Businesses can easily reduce their trash expenses by compaction which lowers the volume of waste produced.

Improved Efficiency

Garbage compactors make waste management easier. For example, one no longer needs to keep track of trash cans or repeatedly replace trash bags with trash compactors. Compactors are also simple to use and don't require any particular abilities.

Better Sanitation

Compaction is a more hygienic method of getting rid of waste since self-contained compactors help isolate waste materials and their by-products.

Increased Workplace Safety

Both dry trash and liquid waste can cause issues at work. If allowed to accumulate, dry waste presents the potential of falling on staff or equipment; it can also present a tripping hazard. Liquids, meanwhile, may leak, or spill and create a slip-and-fall risk. Using a compactor will help to raise and improve workplace efficiency and safety because it lowers, condenses, and stores waste in a designated location.

Promoting Waste Compression

Utilizing a compactor may be advantageous for both end users and waste haulers because of the reduced trash volumes that result from trash compression. End users benefit from reduced volumes of trash needing removal and waste haulers, subsequently, are able to visit more sites before filling their trucks.

Choosing the Correct Trash Compactors Manufacturer

To make sure you have the most productive outcome when purchasing Trash Compactors from a Trash Compactors Company, it is important to compare at least 4 or 5 Manufacturers using our list of Trash Compactors suppliers. Each Trash Compactors Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Trash Compactors business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Trash Compactors companies with the same message.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services