Vertical balers tend to be more compact than horizontal balers and are used in facilities that produce lower amounts of waste, and deal with materials that are light in density and volume. With a large input area on the top of the vertical baler, the scrap or waste material is fed into a compression chamber where it is pounded and squeezed by metal rams into a compact, cubic bale. Vertical balers are generally electrically powered, with hydraulic systems which provide the necessary pressure to crush the materials, and help minimize heat production and energy loss. Read More…

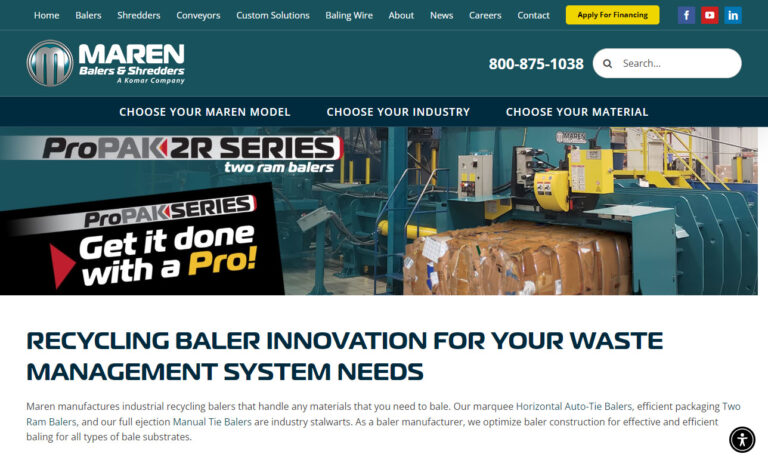

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

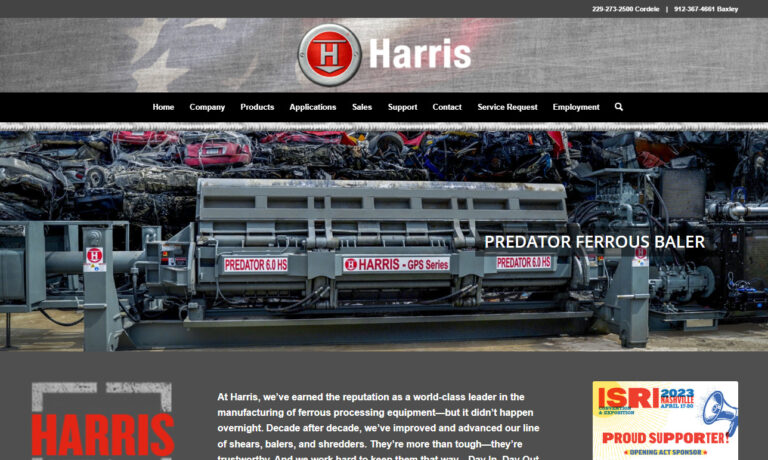

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

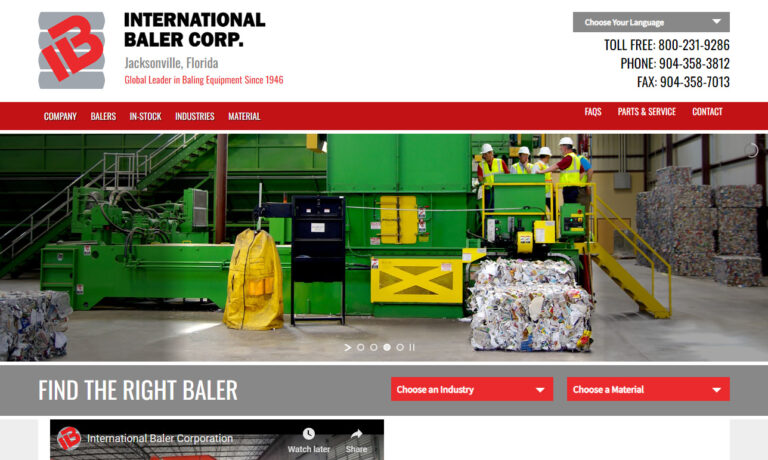

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Vertical Baler Manufacturers

After compression, the cubic bale is tightly bound using wire, plastic or string in order to maintain its compact shape. Vertical balers are typically single-load machines, but multi-bin vertical balers are available that have more than one chamber and can process different types or grades of materials. Output rate is lower for vertical balers whereas horizontal balers are able to run on a continuous process, and to handle heavier, denser materials. Horizontal balers, however, take up more floor space and this needs to be taken into consideration when determining choice of baler.

Typical scrap materials processed with a vertical baler include: corrugated cardboard, shrink-wrap, plastic bottles, aluminum cans and scrap textiles. Loading and unloading of vertical balers is often done manually, but automated systems can be installed to help with the process depending on the baled material. For high waste-producing industries, reducing the bulk of their waste material is important not only environmentally, but also economically.

Using compactors and balers to reduce the volume of waste makes it easier and cheaper to transport and dispose of, and also cuts back on the carbon dioxide emissions produced during the recycling process. Baling equipment is playing an important part in helping industrial businesses to be environmentally friendly.

Materials are baled and compacted in order to be shipped to recycling facilities to be used in producing other items, either within the same industry, or within an entirely different industry. Complete recycling systems can be designed around a basic baler, allowing businesses to be responsible in each stage of their waste management.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services