Aluminum cans have become an essential method for marketing various types of beverages. They are light weight, easy to handle, and a convenient method for transporting and selling refreshing drinks. Since their introduction in 1962, aluminum cans have become a commonly accepted method for selling drinks, powders, and cleaning supplies. Read More…

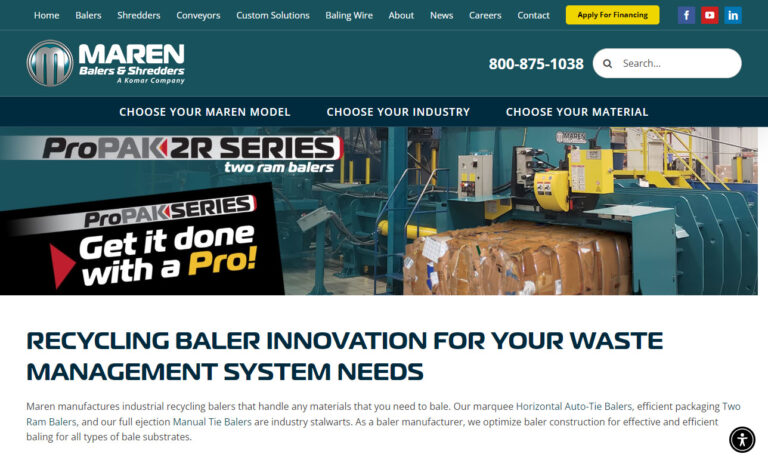

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

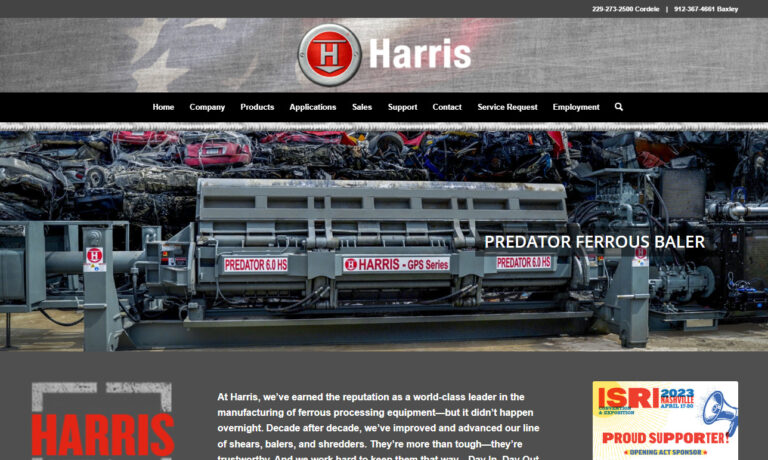

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Aluminum Can Baler Manufacturers

One of the problems that arose because of the widespread production of aluminum cans was their ever-increasing appearance along the side of the road and in waste disposal facilities. Though this was inconvenient, at the time, little consideration was given to how to stop their spread across the landscape.

With the rise in environmental concerns, in the early 1990s, aluminum recycling became a rapidly growing industry capable of reprocessing and repurposing billions of aluminum cans. A critical element in the aluminum recycling industry is the aluminum can baler, which takes scattered and individual cans and reshapes them into bales for convenient use.

What is an Aluminum Can Baler?

In simple terms, an aluminum can baler is a set of hydraulic rams that are designed to compress aluminum cans into a bale. The type of baler depends on the amount of aluminum to be processed, the size of the bale, and the processing equipment.

The simplest form of baler is the vertical type, which can be found in some homes. This form of aluminum can baler is loaded from the top and is capable of producing one bale at a time. It is designed for use by small operations that do not have large amounts of aluminum cans.

The next step up in balers is the horizontal type. For this type of aluminum can baler, the cans are loaded in one side of the baler, compressed, and ejected out the other side. This method is somewhat similar to a production line where aluminum is forced through the line.

The largest type of aluminum can baler uses a conveyor system that loads the cans on a continuous feed from a conveyor belt. The system pours the cans into a hopper that feeds the baler. Quickly and efficiently the bale produces and discharges bales for storage and shipping.

Importance of Aluminum Can Balers

As everyone knows, the amount of landfill space for trash and waste is rapidly shrinking as the world’s population grows. This problem has inspired manufacturers to devise new methods of reusing waste material from commercial products. One of the easiest materials to recycle is aluminum since it does not lose its mechanical properties after being formed.

The baling process takes the millions of tons of aluminum cans and transforms them into easy to store and ship bales that can be immediately placed into the production process. What would be capable of filling a huge area is converted into a rectangular cube.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services