Industrial machinery known as balers or baler machines is employed to collapse a wide range of waste items and byproducts into manageable bundles. These bundles, known as bales, can then be moved, discarded, stored, handled, or recycled more conveniently. Balers come in various forms that fall into general and specialized categories. The cardboard baler is one type of baler with a very particular application. Cardboard and comparable waste items, like paper and plastic, are compressed and bound by cardboard balers. Read More…

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Cardboard Baler Manufacturers

Usually, they do this to recycle the cardboard, whether it is to prepare it for shipping, to store it temporarily, or to reduce the amount of cardboard trash overall. Cardboard baling is widespread in many industries, such as manufacturing, retail, and consumer products and services. This effort is because cardboard, especially in the shape of tubes and boxes, is a regularly utilized item and takes up so much space.

Cardboard Baler Tonnage and Cardboard Balers

The quantity of cargo that cardboard balers create daily, ranging from a few tons for tiny workplaces to thousands of tons for manufacturing and industrial sites, is a crucial differentiator. Therefore, consumers must be aware of how much cardboard must be processed each day when considering buying a cardboard baler. The following are different weights that generally categorize different types of balers:

- 2 tons or less: A mechanically fed machine that creates bales of 2 to 6 feet in length and weighing 100 to 1500 pounds can handle 2 tons or less of cardboard. For vertical balers, this quantity of cardboard is perfect.

- 1 to 4 tons: Bales of cardboard that are over 2 feet wide and 6 feet long and weigh between a half-ton and a ton can be produced using between 1 and 4 tons of cardboard that can be manually fed. A horizontal, fully closed baler is required for this amount of cargo.

- 3 to 200 tons: Heavy-duty, high-productivity cardboard balers are required when the weight of cardboard hits this level. Choosing the horizontal cardboard compactor with an automated feed and tying is determined by the amount of cardboard.

- 200 tons or more: Similar to 3 to 200 tons, the horizontal cardboard baler having automatic feed and tying is required for cardboard waste exceeding 200 tons. A twin ram baler can improve how this amount of cardboard is handled.

Types of Cardboard Balers

Vertical Balers

Vertical balers are reasonably portable and reasonably priced devices for cost-effectively compressing cardboard trash. Due to their compact size, these low-volume cardboard baling presses are perfect for freeing up space in small shops, hotels, restaurants, offices, and gas stations, as well as print and packaging facilities. When a company outgrows its regular recycling bin, dumpster, or cardboard waste container, the smallest-size vertical balers are the ideal answer. A light-duty baling machine is also ideal when there is a modest budget to invest in this machine or when there is a minimal volume of daily cardboard trash.

Horizontal Balers

Vertical balers are smaller than horizontal balers, which are also semi-automatic. They have a feeder at the top into which cardboard can be manually fed and transported using a conveyor belt or cyclone—a system of pipes used at work sites to feed smaller pieces of cardboard. One to 15 tons of cardboard can be produced hourly using horizontal balers, which are intended for enormous quantities.

The pressure range of horizontal baler, which can vary from 20 tons to several hundred tons, is an important feature. They can be continuously fed thanks to their huge capacity. They can self-activate once they have reached a predetermined capacity. Fully closed-end horizontal balers are made for lower bale production, whereas open-ended horizontal balers are made for high production. Horizontal balers can either be closed-ended or open-ended.

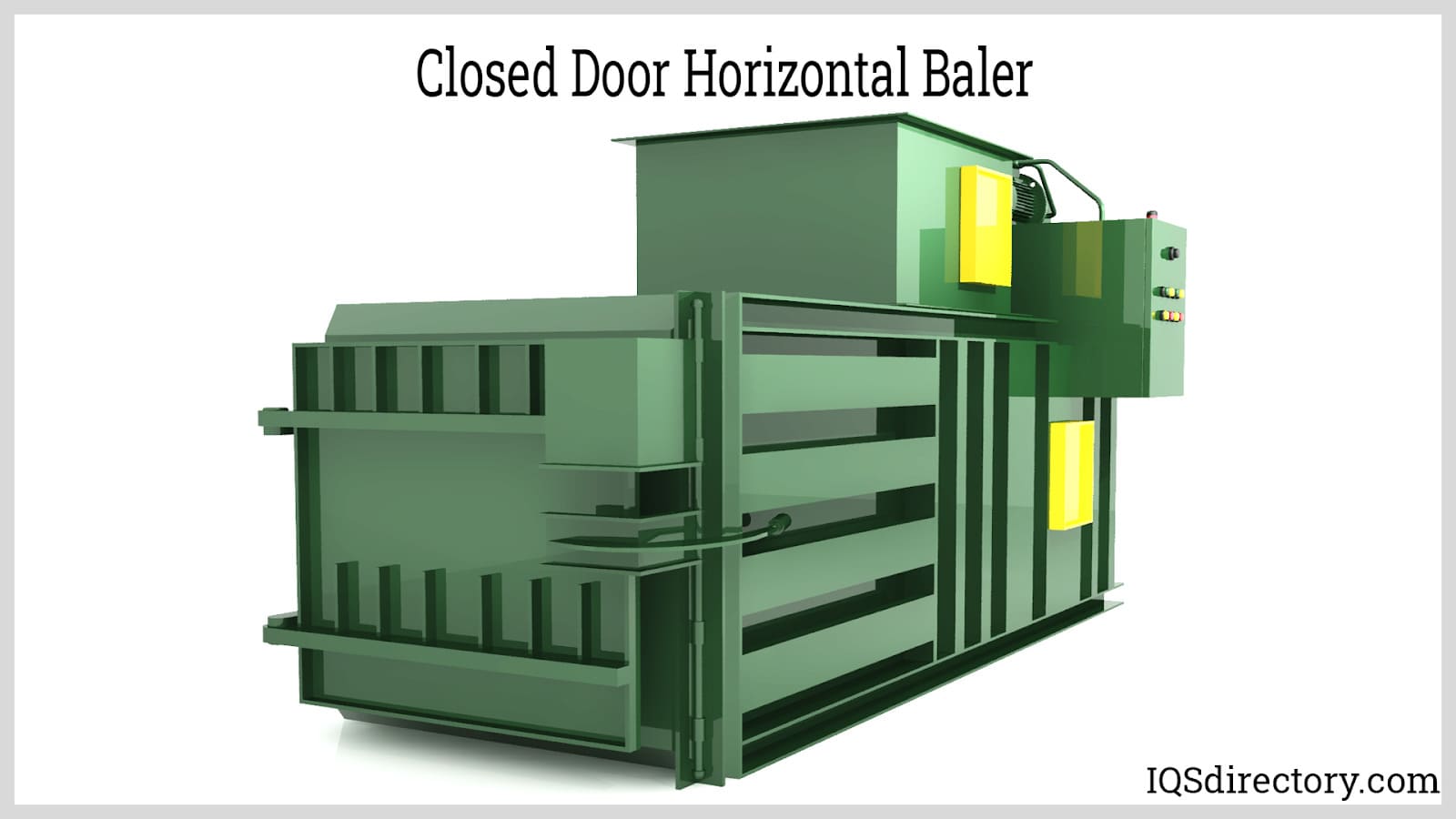

Closed-End Horizontal Balers

Without the assistance of an operator, waste is mechanically squeezed against a closed door. The bale is withdrawn by a back or side door after baling and pushed out by either extending the ram or the next bale. The number of bales that closed-end balers can create per hour, typically one, is their limit.

Open-End Horizontal Balers

They are made for heavy-duty, high-capacity baling for businesses with a lot of cardboard trash. The hopper is filled with materials manually, using a forklift, or via a conveyor. The ram pushes the material towards the extruder's open side by the ram after the hopper is full. Since they don't require human loading or activation, horizontal open-end balers save more labor than vertical balers. However, some variations offer human tying and wiring, and most varieties tie or wire bales automatically. Compared to closed-end horizontal balers, the continuous baling process generates four times as many bales each hour.

Portable Cardboard Balers

Mobile cardboard balers are perfect for businesses with little room and little cardboard. A mobile cardboard baler can produce bales up to 140 pounds in size. The cardboard substance is compressed with vertical downward force. Despite being smaller than their more durable counterparts, portable cardboard balers have a sturdy build.

Choosing the Correct Cardboard Balers Company

To make sure you have the most constructive outcome when purchasing Cardboard Balers from a Cardboard Balers Company, it is important to compare at least 5 or 6 Suppliers using our list of Cardboard Balers manufacturers. Each Cardboard Balers Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Cardboard Balers company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Cardboard Balers businesses with the same quote.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services