Scrap Balers

Scrap balers crush, bale, and compact a broad range of scrap materials for the purpose of recycling or waste recovery. They can allow for the separation of various waste materials and the ability to compact them for collection. Items that can be processed range from small aluminum cans and newspaper to objects as large as vehicles or washing machines. Read More…

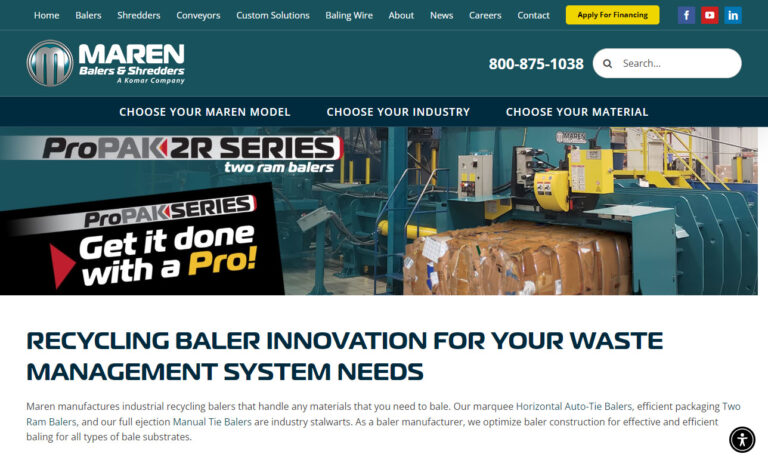

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

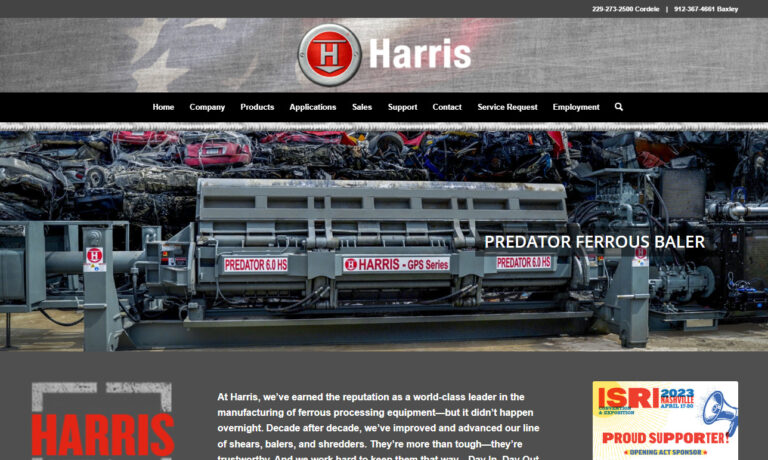

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

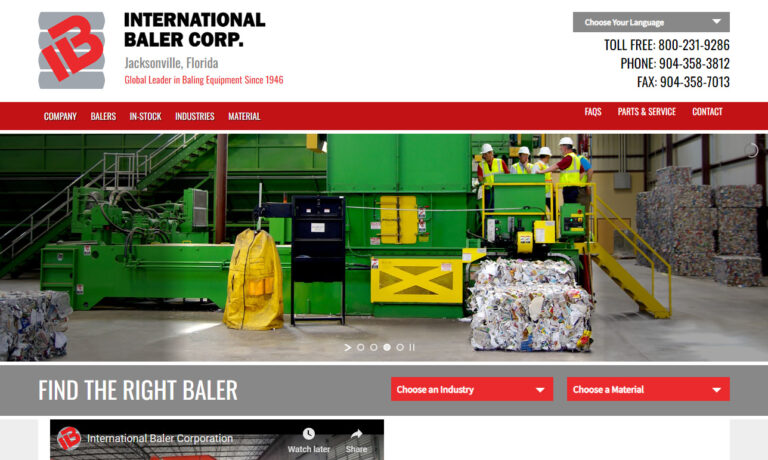

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Scrap Baler Manufacturers

Whenever an application needs scrap materials to be dealt with efficiently, there are balers available that are built specifically for baling certain waste materials of certain quantities. Depending on the needs of the application, scrap balers can be equipped with features such as cranes, graphic operator panels, or remote control abilities, in order to product dense bales at the highest possible rate. Nowadays, there is no single baler configuration that has been in demand for the processing of scrap.

Scrap baling systems can also be equipped with conveyor belts to regulate input and output of scrap materials. Anyone who has visited a scrap facility may encounter a conveyor belt transporting scrap material uphill into a chamber where the material is compressed. Traditionally, these conveyor systems were designed for the scrap material to be dropped downward into a pit, where they are baled and eventually carried back upward to be shipped.

Pit balers can still be found today in recycling facilities throughout North America, but scrap baling systems have grown and changed over the years to become more efficient and more specialized depending on the type of material that needs to be processed. For example, recyclers of non-ferrous metals favor two-ram scrap baling systems due to their heavily-reinforced structure, durability, and flexibility in handling multiple applications.

One can typically find scrap balers in places such as warehouses, drugstores, supermarkets, manufacturing plants, shopping centers, recycling facilities, and distribution centers. No matter what type of baler that a particular business is in need of, scrap balers can provide a variety of profitable and environmental benefits. Due to increased pressure from both the government and society as a whole for business to “go green,” scrap balers have increased in popularity to keep waste to a minimum. In addition, they can assist in increasing storage space, reduce the cost of waste collection, reduce fire hazards, improve efficiency, improve working conditions, and save a company time and money on processing scrap.

Scrap balers can be rented or purchased as standalone machines, or as a model that can be fitted in as part of a larger scrap management system. Baler manufacturers listed here on IQS can help you find the scrap baler that can fulfill the needs of your scrap and non-ferrous metal recycling needs.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services