Industrial balers are utilized by the agriculture, industrial manufacturing, retail, oil, automotive and plastic products manufacturing industries, along with restaurants, schools and junk yards on a regular basis. They use balers to condense any material, including garbage, plastic, metal, paper, cloth and agricultural products like hay. Read More…

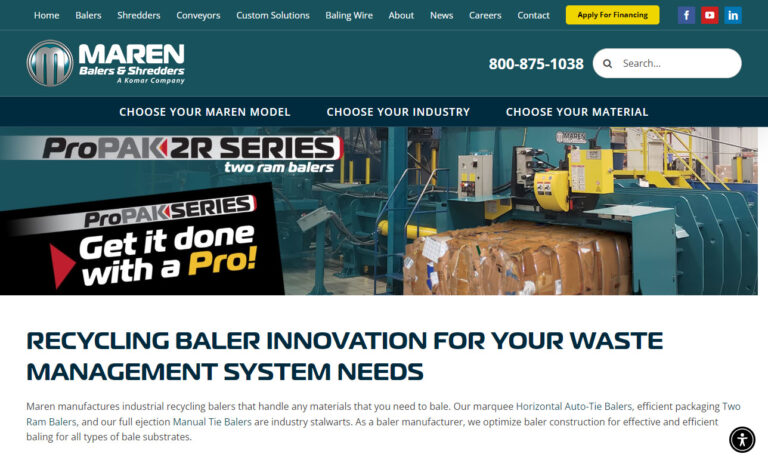

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to...

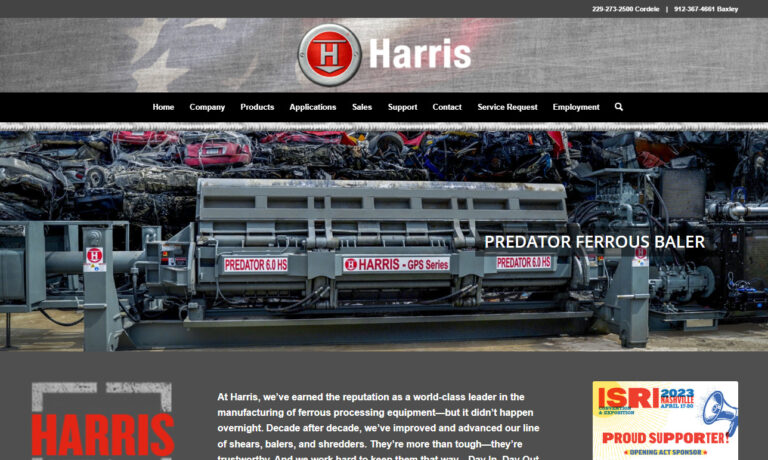

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems provides a wide range of waste management products, including industrial shredders, industrial balers, industrial reducers and industrial compactors.

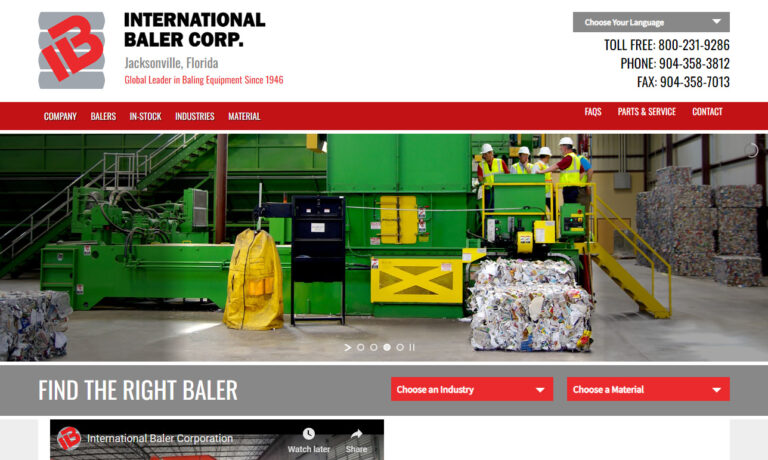

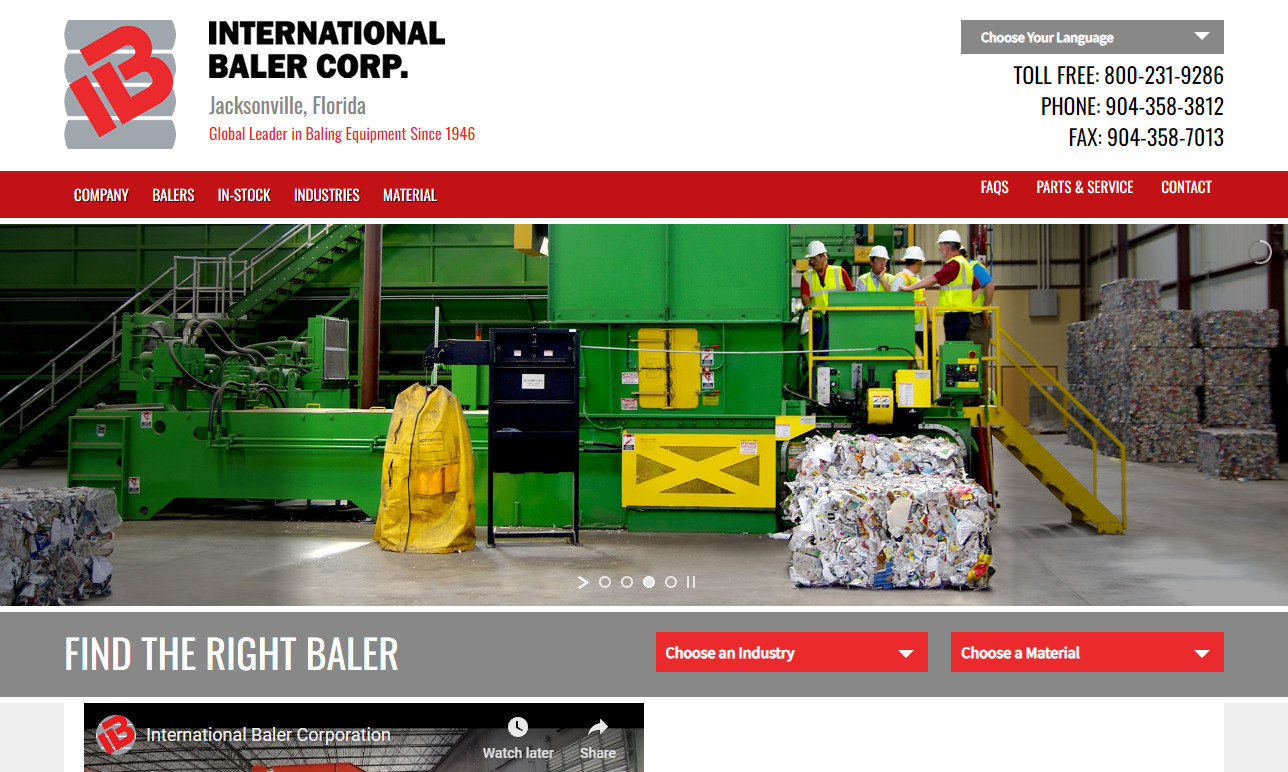

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider International Baler Corporation & our range of balers and related equipment.

More Industrial Baler Manufacturers

Waste materials that will not be recycled are often compacted. This reduces the size of landfills. Most products like plastic bottles, cans and paper, which are recycled, are baled and compressed as part of the recycling process. Perhaps the most common product used in baling, cardboard boxes are found in many industries and can take up a lot of space, money and time, since they are disposable and extremely common. By baling them together, work environments are more organized and recycling is easier. Using balers not only saves space and time, but money as well. The cost of labor is reduced and trash removal fees are lower when handling baled materials.

There are two main types of industrial balers-vertical and horizontal. Horizontal balers take up more floor space but have a greater load capacity, while vertical balers require manual unloading but produce much less waste. Most are powered with an electric motor and use a large metal ram to flatten the material. They also use a hydraulic system that reduces heat and energy loss. Balers are equipped with pumps that remove any leftover liquids from the material, both for sanitary conditions and worker safety.

Industrial balers can be a component of a system and work in conjunction with a conveyor or shredder, or handle material independently. The material or products are fed through the baler, then smashed down by a heavy and powerful ram. Bundles of compressed material are often bound with wire, plastic or string. Often, balers and compactors are often considered interchangeable terms, when in fact, they are different machines. They do similar work, but their specific functions within industries are slightly different.

Balers are mostly used for trash and recycle compacting, as well as agriculture material compacting. They compact and bind materials, while compactors are mostly used to compress and flatten waste materials that are headed to a land fill.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services