Automation R & D

Automation R & DRequest A Quote

Society Hill, SCAutomation R&D is a leading provider of advanced industrial equipment and solutions, with a particular emphasis on balers for a wide range of industrial applications. The company specializes in designing, manufacturing, and servicing innovative and reliable balers that help businesses optimize their waste management operations while reducing their environmental footprint. At Automation R&D, we believe that industrial balers are an essential component of any effective waste management strategy. Our balers are designed to handle a wide range of materials, including paper, cardboard, plastics, textiles, and metals. Our products are engineered to be durable, efficient, and easy to use, with a focus on safety and productivity. Our team of engineers and technicians is dedicated to delivering customized solutions that meet the specific needs of our customers. We work closely with clients to understand their waste management requirements and develop tailored solutions that improve their overall efficiency and profitability. Whether you are looking to optimize your waste management operations, reduce your environmental footprint, or improve your bottom line, Automation R&D is here to help. Contact us today to learn more about our industrial balers and other waste management solutions.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

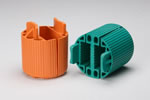

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services